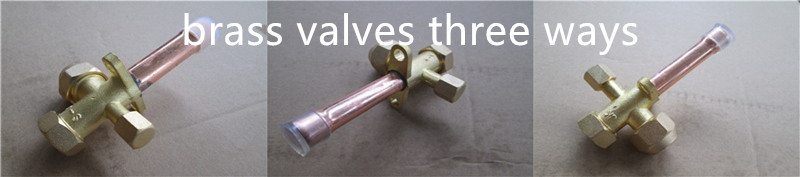

Brass Valve Three ways

Basic Info

Model No.: USM-302

Product Description

The purpose of a 3-way control valve is to shut off water flow in one pipe while opening water flow in another pipe, to mix water from two different pipes into one pipe, or to separate water from one pipe into two different pipes.

A Three way valve is a constant flow rate valve used for either Mixing or Diverting application. In these valves, the total flow rate remains constant. In applications where three way valves are employed, the liquid circuit will naturally split into two separate loops, Constant & Variable flow rate.

The manufacturing features for three way ball valves are the same as other ball valves. The principal function of three ways ball valves is to divert one or more flow streams whilst preventing intermixing.

They are restricted to lower pressure.

Body shape can be 90° or 120°.

T-Port can be used for bypass and mixing of fluids.

L-Port can change the flow direction.

Company Profile

UniSite group was established in 2008 in Ningbo - Chinese second largest port, dredging relevant products manufacturing & supplying since 2005, that is characterized by visible leadership, vitality, innovation, long-term vision and a sound financial position.

As an international partner, we are specialized in providing comprehensive service of dredging, marine engineering, municipal engineering, mechanical engineering, construction machinery, agricultural machinery, port hoisting machinery, metallurgy, automobile, chemical, marine machinery, oilfield projects.

UniSite`s second core activity: serve for machinery and automobile projects

Provide service and relevant parts for mechanical engineering, construction machinery, agricultural machinery, port hoisting machinery, metallurgy, automobile, chemical, marine machinery.

Product range:

A. Big Machining(machining center, boring and milling, lathe)

B. Small Machining(cnc, milling, grinding)

C. Casting (sand, investment)

D. Die casting

E. Forging

F. Stamping and Bending

Product list:

Service Key Customers in the following fields:

- Machinery Products(like Wind Turbine Generate System Hub, Wind Power Bearing Block, Punching Machine Sliding Block, Punching Machine, diesel power generator base, die casting machine base, injection molding machine base, punch, tank, pump parts, accumulators parts, valve parts, construction parts, agricultural parts etc.)

- Machinery Products

- Auto Products

- Shipping building Products

- Medical Products

- Oil Products

Casting

|

| MAIN PARTICULARS |

| Material for product | carbon steel, alloy steel, stainless steel, aluminum alloy, zinc alloy, brass, gray iron, nodular cast iron, ductile Iron or other specified |

| Standard | ASTM, ASME, DIN, JIS, ISO, BS, API, EN |

| Certificate | ISO9001, BV |

| Dimension | As per drawing, as large as we can |

| Processing | Step1:investment casting, Lost wax Casting , sand casting Step2:turning , milling, drilling, grinding, threading, CNC machining |

| Finishing surface | Machined surface with tectyl891, anodize, polishing, nickel plating, zinc plating and chrome plating, oxidation, powder coating, painting, etc. |

| Inspection | material, construction, dimension, heat treatment, hardness, NDT |

| Quality | ISO9001, BV, control production |

See to following photos:

Photos of Brass Valve Three ways

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Casting Parts > Sand Casting Parts